Manual hoist chains are essential tools for lifting and moving loads manually‚ offering reliability‚ cost-effectiveness‚ and versatility across various industries‚ with portable‚ hand-operated designs.

1.1 Definition and Purpose

A manual hoist chain is a portable‚ hand-operated device used to lift‚ lower‚ and position loads safely. Its primary purpose is to provide a reliable‚ cost-effective solution for material handling in various industrial‚ construction‚ and marine settings‚ ensuring precise control and efficiency without the need for external power sources.

1.2 Brief History and Evolution

Manual hoist chains trace their origins to ancient pulley systems‚ evolving over centuries. The Industrial Revolution brought steel chains and mechanical advancements. By the 20th century‚ safety standards and ergonomic designs emerged‚ optimizing efficiency and durability. Modern innovations include lightweight materials and integrated safety features‚ enhancing performance across industries.

Key Components of a Manual Hoist Chain

A manual hoist chain consists of a durable chain‚ a hoist mechanism‚ and a load-bearing system‚ designed to lift and maneuver heavy objects safely and efficiently.

2.1 Chain Construction and Materials

Manual hoist chains are typically made from high-strength‚ durable materials like steel alloys‚ ensuring longevity and resistance to wear. The chains are heat-treated for added strength and often feature corrosion-resistant coatings to withstand harsh environments‚ enhancing both flexibility and durability while maintaining safety standards.

2.2 Hoist Mechanism and Gearing

Manual hoist chains operate via a mechanical gearing system that reduces effort required for lifting. The gears are precision-engineered to distribute load stress evenly‚ ensuring smooth operation. This mechanism allows for precise control over load movement‚ enhancing efficiency and safety in various lifting applications.

2.3 Load Capacity and Safety Features

Manual hoist chains are designed with specific load capacities to ensure safe operation. Safety features include overload protection‚ secure latching mechanisms‚ and durable materials. These elements prevent accidents and extend the lifespan of the hoist‚ making them reliable for industrial and construction applications.

Types of Manual Hoist Chains

Manual hoist chains come in various types‚ including hand chain hoists‚ lever-operated hoists‚ and specialized designs for specific industries‚ each tailored for unique lifting requirements and environments.

3.1 Hand Chain Hoists

Hand chain hoists are portable‚ manually operated devices using a chain and pulley system for lifting loads. They are cost-effective‚ easy to maintain‚ and ideal for small-scale operations‚ offering precise control and reliability in various industrial and construction settings.

3.2 Lever-Operated Hoists

Lever-operated hoists provide efficient‚ manual lifting solutions with a lever mechanism for easy operation. Designed for heavy-duty applications‚ they offer durability‚ precise load control‚ and are suitable for industrial and marine environments‚ ensuring safety and reliability in demanding conditions with minimal maintenance requirements.

3.4 Specialized Hoists for Specific Industries

Specialized hoists are tailored for niche applications‚ such as marine‚ theater rigging‚ and construction. They feature industry-specific designs‚ like corrosion-resistant materials for marine use or silent operation for stages‚ ensuring optimal performance and safety in unique environments while adhering to strict industry standards and regulations.

Advantages of Using Manual Hoist Chains

Manual hoist chains offer cost-efficiency‚ portability‚ and reliability‚ functioning without electricity‚ making them ideal for remote or power-outage scenarios‚ while requiring minimal maintenance and training.

4.1 Versatility in Various Applications

Manual hoist chains are adaptable across industries‚ from construction and manufacturing to marine and stage rigging‚ offering efficient load handling in diverse settings due to their portability and ease of use‚ making them essential tools for both small-scale and large-scale operations.

4.2 Cost-Effectiveness Compared to Motorized Hoists

Manual hoist chains are more affordable than motorized alternatives‚ requiring lower initial investment and maintenance costs. They eliminate the need for electricity‚ reducing energy expenses and offering a practical solution for smaller-scale operations‚ making them a budget-friendly choice for various lifting needs.

4.3 Ease of Operation and Maintenance

Manual hoist chains are straightforward to operate‚ requiring minimal training and effort. Their simple design ensures easy maintenance‚ with tasks like lubrication and chain inspection being quick and accessible‚ reducing downtime and extending equipment lifespan‚ making them a practical choice for multiple applications.

4.4 Reliability in Power-Outage Scenarios

Manual hoist chains provide consistent functionality without electricity‚ ensuring operations continue during power outages. Their mechanical simplicity and independence from electrical systems make them indispensable in critical situations‚ offering a dependable solution for lifting tasks when motorized alternatives fail.

Safe Operation and Best Practices

Safe operation of manual hoist chains requires regular inspections‚ proper load management‚ and adherence to established safety guidelines to prevent accidents and ensure efficient functionality.

5.1 Pre-Operational Checks and Inspections

Conducting thorough pre-operational checks ensures manual hoist chains function safely. Inspect chains for wear‚ test load brakes‚ and verify all components are secure. Lubricate moving parts to prevent friction and extend lifespan. Always refer to the manufacturer’s guidelines to perform these checks accurately and maintain operational reliability.

5.2 Proper Load Securing Techniques

Ensure loads are balanced and centered on the hoist hook to prevent tipping. Use appropriate straps or slings to secure the load‚ avoiding direct contact with the chain. Tighten all fasteners evenly and test the setup before lifting to guarantee stability and safety during operation.

5.3 Operator Training and Safety Protocols

Operators must receive hands-on training to understand manual hoist chain operations‚ load limits‚ and emergency procedures. Regular safety drills and adherence to industry standards ensure efficient and secure lifting processes‚ minimizing risks and enhancing workplace safety.

Maintenance and Repair of Manual Hoist Chains

Regular lubrication‚ chain inspections for wear‚ and proper storage are essential for maintaining manual hoist chains; Prompt repairs prevent damage and ensure safe‚ efficient operation.

6.1 Regular Lubrication of Moving Parts

Lubricating moving parts of manual hoist chains is crucial for smooth operation. Apply high-quality grease to gears and hinges to reduce friction and wear. Regular lubrication prevents corrosion‚ ensuring longevity and reliable performance under various conditions. Always use manufacturer-recommended lubricants to maintain optimal functionality and safety standards.

6.2 Chain Inspection for Wear and Damage

Inspecting manual hoist chains regularly is vital for safety. Check for signs of wear‚ such as elongation‚ rust‚ or broken links. Replace any damaged components immediately to prevent equipment failure. Use calibrated tools to measure chain stretch and ensure compliance with safety standards‚ maintaining reliability and operational integrity.

6.3 Storage and Protection from Environmental Factors

Store manual hoist chains in a dry‚ cool place to prevent rust and damage. Protect them from direct sunlight‚ moisture‚ and chemicals. Clean chains before storage and apply a protective coating or lubricant to maintain condition. Proper storage ensures longevity and reliability‚ preventing environmental degradation and maintaining operational readiness.

Applications of Manual Hoist Chains

Manual hoist chains are widely used in industrial settings‚ construction sites‚ and marine environments for lifting and moving heavy loads. They are also essential in stage rigging and event setups.

7.1 Industrial and Construction Settings

Manual hoist chains are indispensable in industrial and construction environments for lifting heavy machinery‚ materials‚ and equipment. They provide reliable‚ portable solutions for moving loads in workshops‚ warehouses‚ and building sites‚ ensuring efficiency and safety where motorized options may not be feasible or practical.

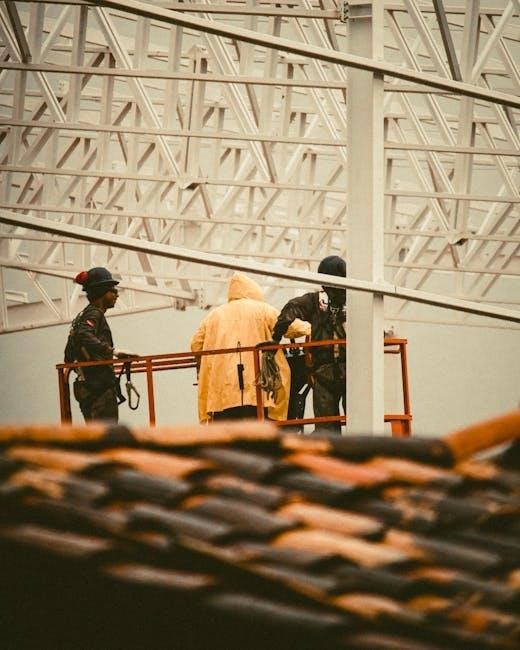

7.2 Marine and Offshore Environments

Manual hoist chains are crucial in marine and offshore settings for lifting cargo‚ anchors‚ and equipment. Their durability and resistance to harsh conditions make them ideal for use on ships and rigs‚ ensuring reliable operation in saltwater and high-stress environments where failure is not an option.

7.3 Stage and Event Rigging

Manual hoist chains are widely used in stage and event rigging for lifting lighting‚ sound equipment‚ and scenery. Their portability‚ ease of use‚ and precise control make them essential for creating dynamic setups in theaters‚ concerts‚ and live events‚ ensuring smooth and safe operations behind the scenes.

Future Trends in Manual Hoist Technology

Manual hoist chains are evolving with smart technology for real-time monitoring‚ lightweight materials for durability‚ and enhanced safety mechanisms‚ improving efficiency and user protection in future applications.

8.1 Integration of Smart Technology

Smart technology integration enhances manual hoist chains with sensors and IoT connectivity‚ enabling real-time monitoring‚ predictive maintenance‚ and data-driven insights. This innovation improves operational safety‚ reduces downtime‚ and optimizes load management‚ setting a new standard for efficient and intelligent lifting solutions in various industries.

8.2 Development of Lightweight and Durable Materials

Advanced materials like high-strength polymers and lightweight metals are being developed to enhance manual hoist chains. These innovations reduce weight without compromising strength‚ improving safety and durability. The extended lifespan and improved performance make them suitable for diverse industrial applications‚ ensuring reliability and efficiency in lifting tasks with less maintenance.

8.3 Enhanced Safety Mechanisms

Modern manual hoist chains incorporate advanced safety features‚ such as overload protection‚ emergency braking systems‚ and smart load sensors. These innovations ensure safer operations by detecting potential risks and preventing accidents. Enhanced safety mechanisms also include improved chain locking systems and durable coatings to withstand harsh environments‚ reducing maintenance and extending service life.

Troubleshooting Common Issues

Troubleshooting manual hoist chains involves identifying issues like chain jamming‚ uneven lifting‚ or mechanism failure. Regular inspections and maintenance help resolve problems promptly‚ ensuring smooth operation.

9.1 Chain Jamming or Binding

Chain jamming or binding occurs when the chain fails to move smoothly‚ often due to dirt‚ misalignment‚ or excessive wear. Regular cleaning‚ proper lubrication‚ and ensuring the chain is correctly seated in the mechanism can prevent this issue. Immediate attention is crucial to avoid further damage or operational downtime.

9.2 Load Imbalance or Uneven Lifting

Load imbalance occurs when the weight is not evenly distributed‚ causing uneven lifting. This can lead to tilting or swinging‚ potentially damaging the hoist or load. Proper load securing‚ ensuring the chain is centered‚ and using balance aids can prevent this issue. Regular operator training is essential to avoid such scenarios.

9.3 Gearbox or Mechanism Failure

Gearbox or mechanism failure in manual hoist chains often results from overloading‚ insufficient lubrication‚ or wear over time. Symptoms include noisy operation or difficulty lifting loads. Troubleshooting involves disengaging the load‚ inspecting for damage‚ and replacing worn parts. Regular lubrication and maintenance can prevent such failures‚ ensuring smooth operation and longevity.

Purchasing Considerations

When buying manual hoist chains‚ consider load capacity‚ environmental conditions‚ and brand reputation to ensure durability‚ safety‚ and suitability for specific applications and industries.

10.1 Load Capacity and Duty Cycle

Selecting a manual hoist chain requires evaluating its load capacity and duty cycle to ensure it meets operational demands. The chain must handle the maximum weight and frequency of lifts safely‚ preventing overload and extending equipment lifespan‚ while adhering to industry standards for reliable performance in various environments.

10.2 Environmental and Application-Specific Requirements

Ensure the manual hoist chain meets environmental and application-specific needs. Consider factors like corrosion resistance for marine settings‚ durability for construction‚ and specialized coatings for harsh conditions. Matching the hoist to its use ensures optimal performance‚ safety‚ and longevity in diverse operational environments‚ from industrial to offshore applications‚ enhancing reliability and efficiency.

10.3 Brand Reputation and Warranty

When purchasing a manual hoist chain‚ consider the manufacturer’s reputation for quality and reliability. A reputable brand often provides comprehensive warranties‚ ensuring coverage for repairs and replacements. This support enhances long-term value‚ offering peace of mind and financial protection against potential failures or defects in the equipment over time.

Manual hoist chains remain indispensable tools in various industries‚ offering versatility‚ reliability‚ and cost-effectiveness. Their simplicity ensures wide applicability‚ while ongoing innovations promise enhanced performance and safety. Selecting a reputable brand with robust warranties is crucial for long-term satisfaction and operational efficiency.